This innovative, patented, industry first 3D printed Microchannel heat sink transfers high-density heat from the surface of the load to the liquid cooling system with unrivaled reliability and efficiency. TurboPlate has revolutionized how the world cools servers, medical equipment, power batteries, IGBTs, inverters, lasers generator, semiconductors and other high density heat generation devices.

TurboPlateTM - 3D Printed Microchannel Heat Sink

Outstanding Cooling Performance

The patented microchannel design allows the two phase dielectric liquid to reach the lowest pressure drop, the best distribution and the lowest flow rate. The 3D printing technology make the mass manufacturing possible at effective cost. TurboPlateTM sets an industry record of 50W/ cm2 cooling density.

Single-phase cold plate vs. TurboPlateTM @ the equivalent heat load, surface temperature and liquid inlet temperature.

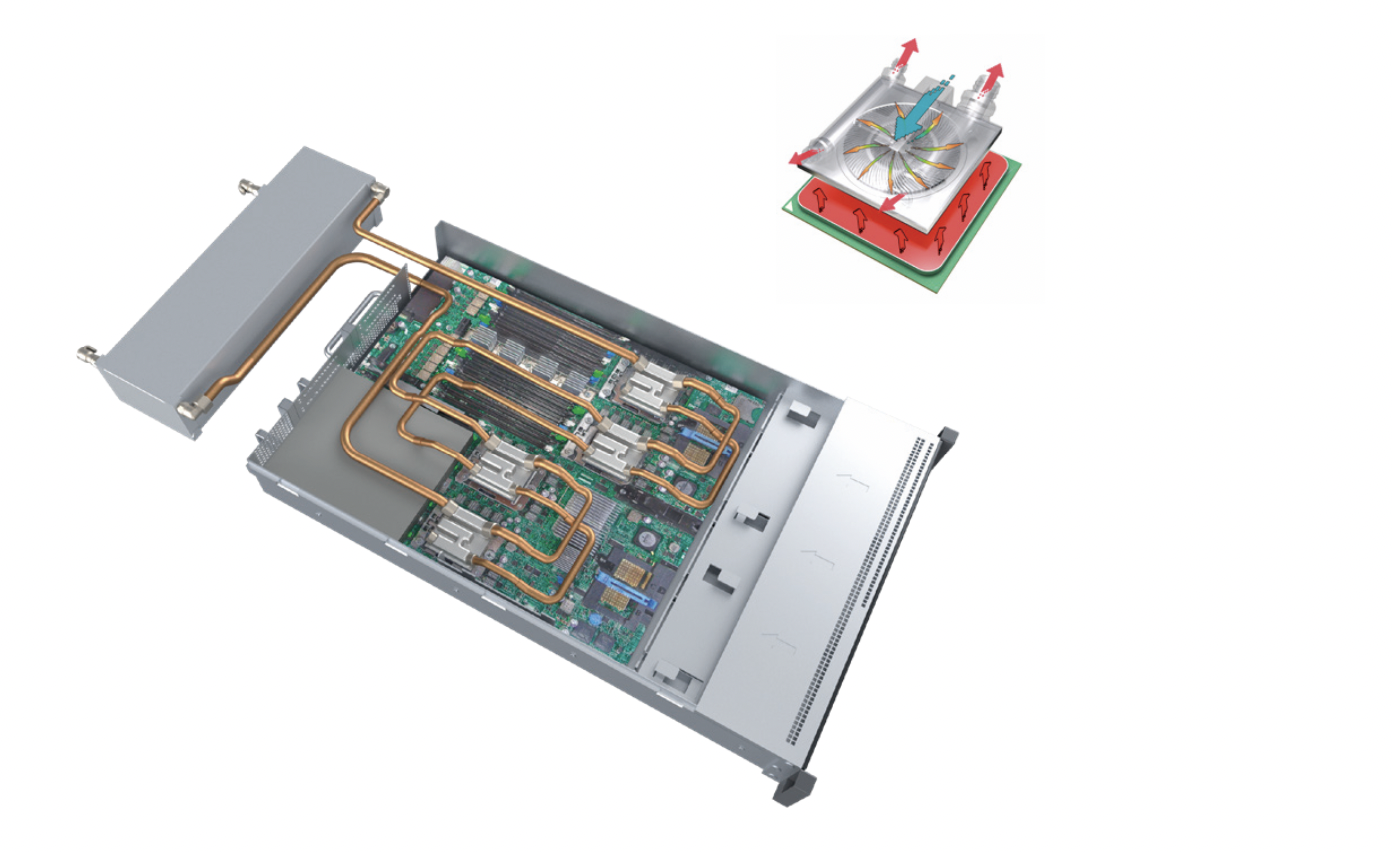

Multiple Heat Sinks Are Connected in Parallel

TurboPlateTM patented parallel system design allows the optimum equilibrium of cooling among multiple heat sources. This feature will fundamentally solve the issue of over cooling/heating caused by serial system which is still the industry standard.

High Liquid Temperature for 100% Free Cooling and Full Waste Heat Recovery

TurboPlateTM reduces the delta T between the liquid inlet temperature and heat source surface temperature from 50-60°C to 15-20°C as a result of its patented micro-channel technology.

Surface temperatrue of CPU is about 80°C, while for IGBTs, the maximum case temp can be 120°C or even higher. ALCT can offer customized dielectric fluid to realize efficient heat exchange at such a high temperature, and obtain max. 95 °C hot water from heat recovery.

Modular Design, Customization

The concept of modular design leads to lower manufacturing cost and shorter design to delivery cycle. A standard 7*7cm module can be assembled to deliver wide range of cooling capacities. In addition, our R&D team is able to design and deliver custom modules with our in-house ability of CFD and verification Lab, to meet any customers’ special requirements.

TurboPlateTM is a game-changing technology which allows those equipment manufactures to redefine, redesign their products in terms of size, capacity, cost and application. Furthermore, by using the recovered heat, it will make the “Net-Zero Emission” goal much more achievable in the years to come.